Product Categories

Feeder

This feeder is a device used for automatically conveying materials. It transports granular or powdery raw materials from storage equipment to extruders or mixers through methods such as vacuum suction, screw conveying, or pneumatic conveying, achieving efficient and continuous material supply. The feeder features simple operation, high automation, and fast conveying speed. It can effectively reduce manual labor intensity, improve production efficiency, and maintain a clean production environment. Common types include vacuum feeders, screw feeders, and gravity feeders, which can be flexibly selected according to material characteristics and production requirements.

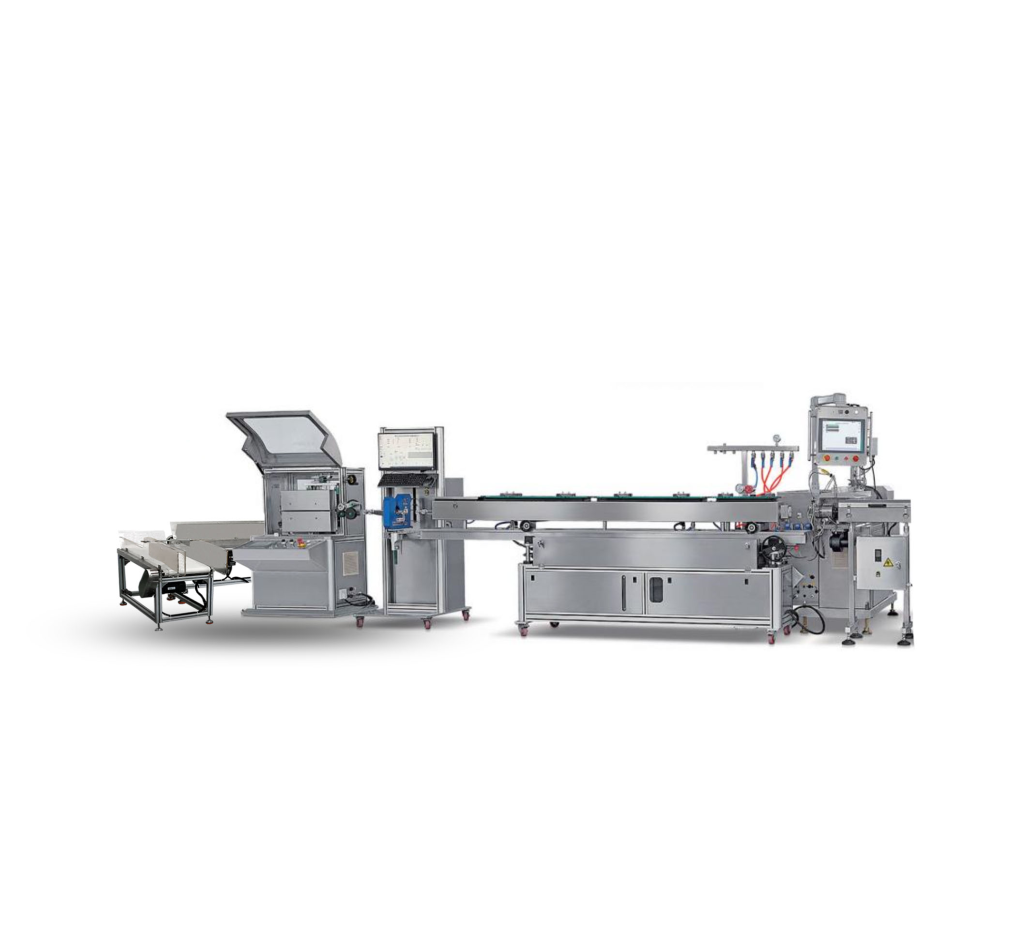

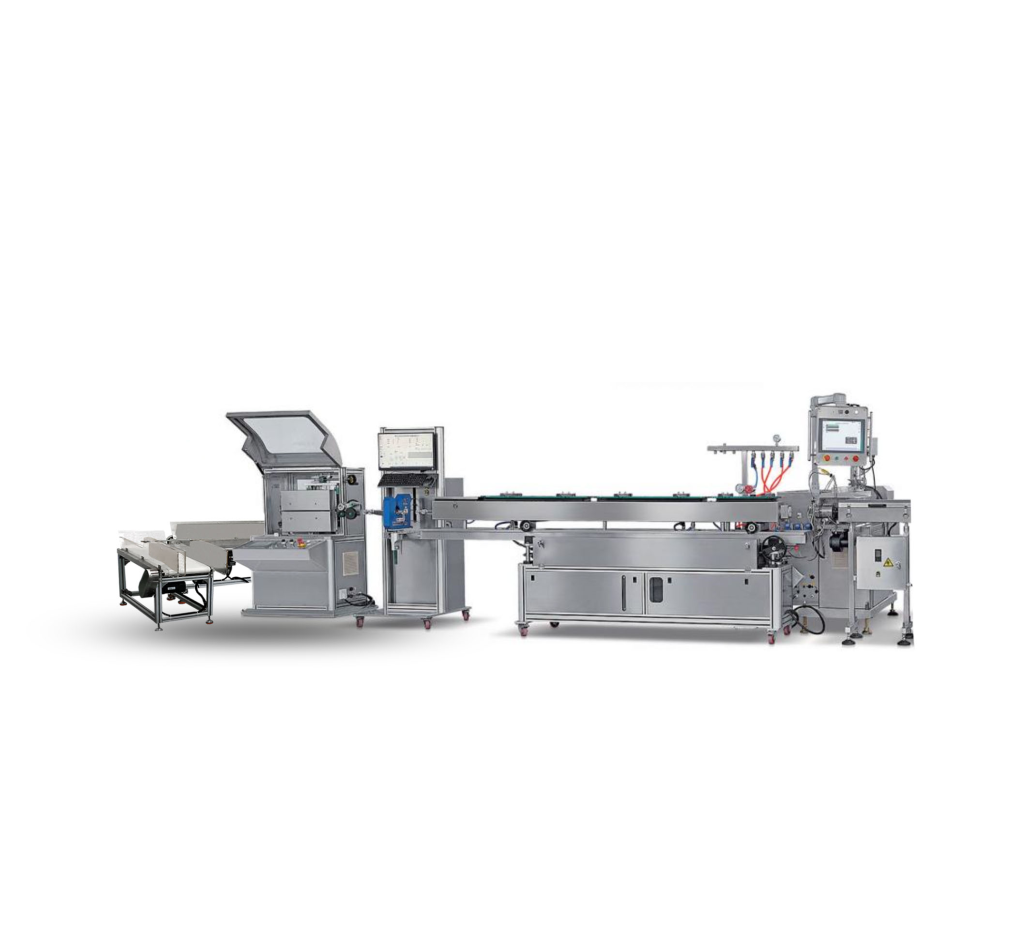

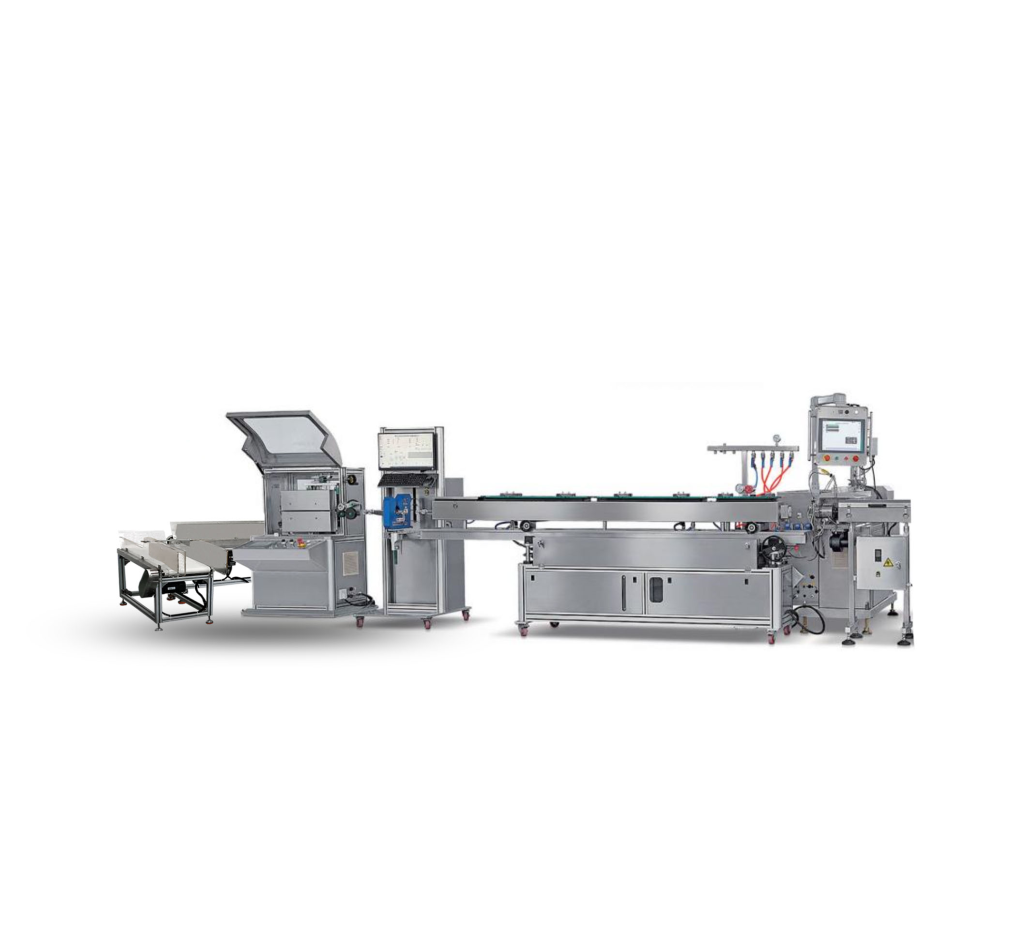

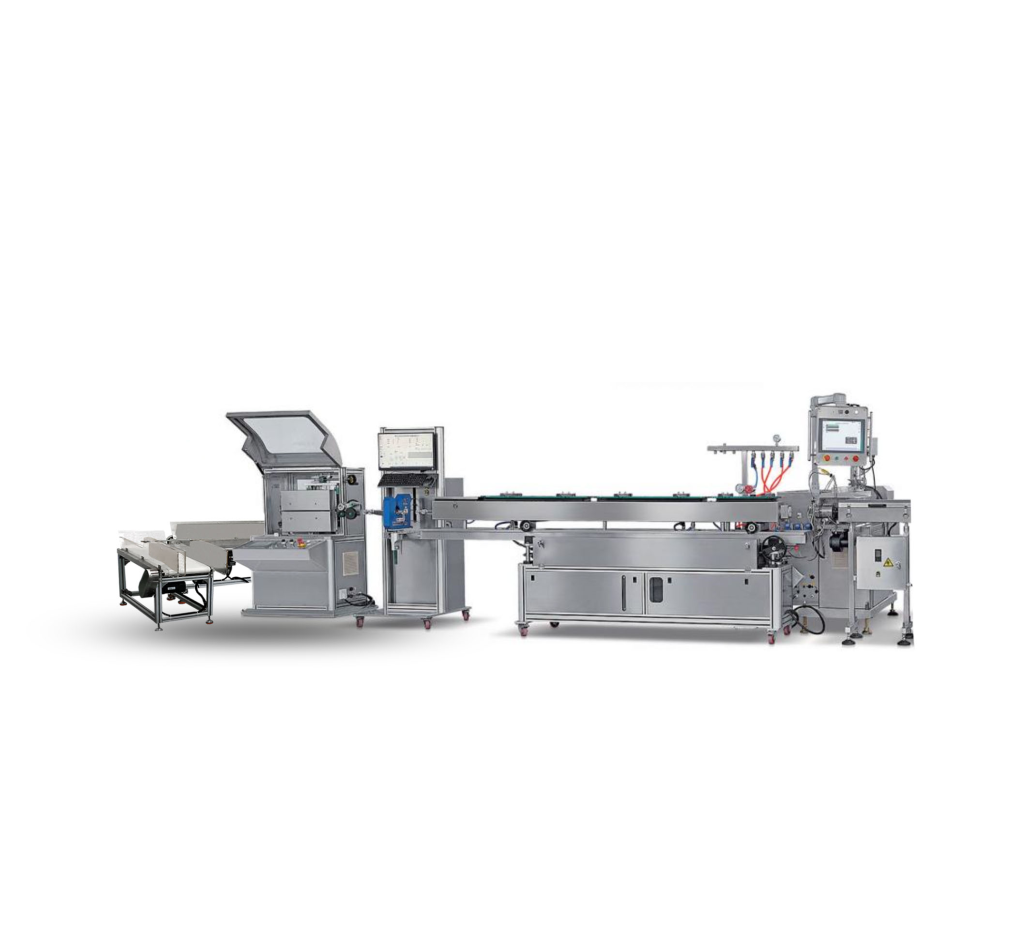

Cooling Tank

This cooling tank is an important device used for cooling and shaping extruded products in plastic extrusion production lines. It is widely applied in the production process of plastic products such as pipes, profiles, and rods. By quickly immersing the high – temperature extruded products into the circulating cooling water, the cooling water tank can effectively lower the product temperature, ensuring its shaping and dimensional stability. Usually made of stainless steel, the cooling water tank is corrosion – resistant and easy to clean. It is equipped with a water circulation system and a water level adjustment device to ensure cooling efficiency and uniformity. Some cooling water tanks are also equipped with automatic adjustment brackets and guiding devices to meet the production requirements of different product specifications.

Puller

This puller is a device specially designed to stably and uniformly pull extruded pipes, profiles, rods, or sheets through processes such as the cooling water tank and cutting device, ensuring product size consistency and quality stability. The tractor usually consists of a traction belt, traction wheels, or crawlers, with adjustable traction speed and pressure to meet the needs of different materials and production speeds. Its high – precision control system can prevent product deformation or damage, improving production efficiency and product qualification rate.

Winding Machine

This winding machine is the terminal device of the plastic extrusion production line, specifically used for neatly winding the finished plastic pipes, sheets, or wires into rolls for easy storage, transportation, and subsequent processing. The winder is usually equipped with an automatic tension control system and a synchronous speed adjustment function to ensure the uniform arrangement and appropriate tightness of the materials during the winding process, avoiding surface damage or deformation of the products. According to material characteristics and specifications, winders can be designed as single – station, double – station, or multi – station to meet different requirements of continuous production.