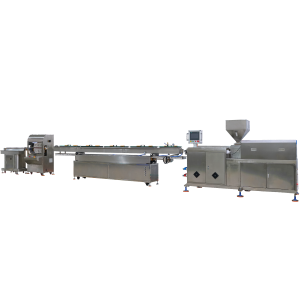

I. Equipment Overview & Core Functions

Medical pipe extruder production line are precision plastic processing systems designed for producing catheters, oxygen tubes, drainage tubes, and other medical devices. Core objectives include:

Precision control of temperature/pressure for ISO 13485 compliance

Ultra-tight tolerances (±0.02mm dimensional stability)

Biocompatibility and sterile manufacturing

II. Equipment Structure & Key Technologies

1. Main System

Screw & Barrel:

Nitrided alloy steel (38CrMoALA) or quenched steel (9Cr18MoV)

Compatible with medical-grade PVC, PP, PE, PU

Drive System:

Servo motor + precision frequency converter

<1% extrusion speed fluctuation

2. Die & Flow Channel Design

S136 tool steel molds with mirror-polished channels

Multi-lumen dies for dual-color/multi-channel tubes (e.g., triple-lumen venous catheters)

3. Cooling & Sizing System

Closed SUS304 stainless steel water tanks with vacuum calibration

Hermetically sealed blow-dry units preventing water residue (cleanroom-compatible)

4. Haul-off & Cutting System

Servo-driven multi-V-belt haul-off (≤0.1mm synchronization error)

PLC-programmed rotary cutters (±0.5mm length tolerance, burr-free)

III. Materials & Process Characteristics

Materials

USP Class VI certified polymers: PVC (transparent O₂ tubes), PP (infusion tubes), PU (urinary catheters), silicone

Specialty compounds: Antibacterial PE, radiopaque composites

Process Control

Zoned temperature profiles:

Feeding zone: 185-195°C

Compression zone: 180°C

Metering zone: 170-175°C

Melt gear pumps reducing pressure fluctuations by 70-90%

IV. Quality Control & Certification

Real-time monitoring:

Laser micrometers with closed-loop adjustment

SPC (Statistical Process Control) for batch consistency

GMP-compliant environment:

HEPA filtration

Positive-pressure dust prevention

V. Key Applications

Clinical Therapy: Nasal cannulas, anesthesia tubes, central venous catheters

Diagnostics: Hemodialysis tubes, microfluidic chips

Surgical Tools: Laparoscopic trocars, endotracheal tubes

VI. Industry Trends

Smart Manufacturing: IoT integration for remote diagnostics

Miniaturization: Sub-0.5mm catheters for minimally invasive surgery

Sustainability: PLA biodegradable materials + 3D printing hybridization

Conclusion

Medical pipe extruders merge precision engineering, material science, and automation to meet stringent medical safety requirements. Future advancements will focus on eco-friendly customization and micro-scale production capabilities.