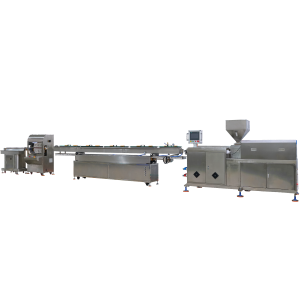

I. Equipment Positioning & Core Features

Parameter Adaptability

- Model: HPJX-CPE-01 (modular design, compatible with single/double-wall corrugated pipe production)

- Applicable Materials: Rigid polymers (PVC, HDPE, PP) and flexible compounds (TPU, TPE, EVA), covering scenarios like building drainage and automotive wire harness protection

- Pipe Diameter Range:

- Single-wall: 10–50 mm (micro cable conduits)

- Double-wall: 16–63 mm (municipal drainage pipes)

Performance Advantages

- Tiered Output: 150/300/500 kg/h (screw diameters: 60/75/90 mm), adaptable to varied capacity needs

- High-Speed Production: Up to 30 m/min for HDPE double-wall pipes with corrugation forming modules.

II. Core Components & Technological Innovations

Extrusion System

- Screw Design:

- 60mm Screw (L/D ratio 25:1): Optimized for high-viscosity materials (e.g., TPU) at low-speed, high-torque extrusion (15–40 rpm).

- 90mm Screw (L/D ratio 30:1): Suited for HDPE high-speed extrusion (50–90 rpm), featuring double-threaded flights in compression zone for enhanced mixing.

- Temperature Control: 4–6 independent zones (±1°C precision), e.g., gradient cooling for PVC (185°C feeding → 165°C die).

Corrugation Forming Unit

- Modular Molds: Quick-change corrugation modules (tooth/sine wave profiles), precision ±0.2 mm.

- Vacuum Adsorption:

- Single-wall: Negative pressure forming (-0.08 MPa vacuum).

- Double-wall: Combined with internal pressure blow molding (0.3–0.5 MPa).

Cooling & Calibration System

- Three-Stage Cooling:

- Spray pre-cooling (15–20°C water)

- Vacuum calibration (8m SUS304 water tank)

- Air-knife drying (compressed air dewatering).

III. Material & Process Optimization

Material-Specific Adaptation

- HDPE Double-Wall Pipes: Single-screw + melt gear pump (pressure fluctuation <5%), paired with 22kW drive motor.

- TPU Flexible Pipes: Bimetallic barrel (250°C resistance) + forced feeder to prevent material slippage.

Production Process

- Preprocessing: Dehumidification drying (dew point -40°C, HDPE moisture ≤0.02%).

- Co-Extrusion: Supports dual-color/dual-material (e.g., UV-resistant PP outer layer + conductive TPE inner layer).

- Online QC: Laser micrometer (0.02 mm precision) + IR thermal imager for real-time corrugation pitch monitoring.

IV. Typical Applications & Configuration Advice

| Application | Recommended Configuration | Key Technical Indicators |

|---|---|---|

| Building Drainage | 75mm screw + 300kg/h mode | Ring stiffness ≥8 kN/m² |

| Automotive Vent Ducts | 60mm screw + TPU-dedicated die | Temp. resistance: -40°C~120°C |

| Farm Irrigation Pipes | 90mm screw + double-wall co-extrusion | Burst pressure ≥0.6 MPa |

V. Smart & Energy-Saving Design

Intelligent Control

- HMI Interface: Stores 50+ process recipes, enables PLC-synchronized control between corrugator and haul-off (speed sync error ≤0.1%).

- Remote Monitoring: IoT-enabled data upload to MES for real-time production analytics.

Energy Efficiency

- Electromagnetic Heating: 40% lower energy vs. resistive heating.

- Waste Heat Recovery: Recycles cooling water for raw material pre-drying.

Conclusion

The HPJX-CPE-01 achieves full-spectrum production from micro flexible conduits to large drainage pipes through multi-tier screw configurations, modular corrugation forming, and precision temperature control. Its 500 kg/h max. output meets municipal project demands, while the 30:1 L/D screw ensures uniform plasticization for high-MFI polymers like TPU. For optimal configuration, prioritize servo-driven systems based on material properties (e.g., melt flow index) and corrugation complexity.