I. Core Equipment Positioning

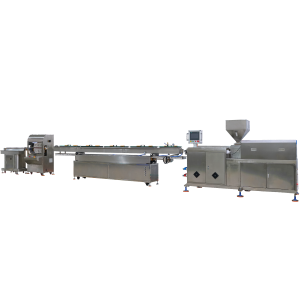

The HPJX-CE-01 is a high-efficiency extrusion system designed for precision coating of multiple substrates, achieving breakthrough integration of 10+ polymers and 6 substrate types for applications in cable reinforcement, building profiles, and automotive lightweighting. Core advantages:

- Ultra-high-speed coating: 80 m/min (industry average ≤30 m/min)

- Ultra-thin layer control: 0.1 mm precision → material cost savings ↑40%

- Smart substrate adaptation: Seamless switching between metal/wood/glass fiber.

II. Modular Technical System

1. Extrusion System: Multi-Material Compatibility

| Parameter | Technical Solution |

|---|---|

| Screw Grading | – 20 mm screw (5.5 kW): TPU thin-layer coating (0.1–0.5 mm) |

| – 80 mm screw (45 kW): PC thick-layer coating (3–5 mm, adhesion >50 N/cm) | |

| Temp Control | 5-zone PID (±1°C): |

| – Low-temp zone (170–190°C): Prevents TPU yellowing | |

| – High-temp zone (280–300°C): Enhances PC adhesion | |

| L/D Ratio | 30:1 high compression → ↑35% melt penetration for PA-coated metal |

2. Coating Die & Substrate Treatment

- Multi-channel co-extrusion:

- Dual-layer coating: Primer (↑ adhesion) + functional layer (UV/flammability resistance)

- Direct coating on wood (moisture ≤8%) → prevents bubbling.

- Substrate pretreatment:

- Metal plasma cleaning (dyne level >54 mN/m)

- Glass fiber activation coating → ↑ polymer bonding.

3. Cooling & Calibration System

| Component | Technical Solution |

|---|---|

| Quenching | Spray water cooling (5–10°C): Rapid solidification of 0.1 mm layers (anti-sag) |

| Slow Cooling | Air-cooled tunnel (20–25°C): Eliminates internal stress in thick coatings (>3 mm) |

| Online QC | Laser thickness gauge (±0.02 mm) + IR thermal imager (temperature deviation alarm) |

4. Downstream Processing

| Component | Technical Solution |

|---|---|

| Haul-off | – Caterpillar type (max. 15 kN): Rigid traction for steel-core coating |

| – Roller type (PID tension control): Prevents wood substrate damage | |

| Cutting | – Planetary cutting: For coated steel pipes (Φ>50 mm) |

| – Chip-free cutting: Electronic cables (cutting surface Ra≤1.6 μm) | |

| Winding | – Auto-winding: Tension fluctuation <3% (cables/profiles) |

| – Fixed-length cutting: Precision ±0.5 m (engineering parts) |

III. Typical Applications & Processes

| Application | Product Case | Process Highlights |

|---|---|---|

| Cable Reinforcement | TPU-coated optical fiber (0.2 mm) | 80 m/min + water quenching |

| Building Profiles | PVC-coated aluminum window frame (1.5 mm) | Plasma cleaning + primer co-extrusion |

| Auto Lightweighting | PA-coated Mg alloy steering frame | Pre-heated to 120°C + high-pressure penetration coating |

| Medical Devices | PC-coated surgical scalpel handle | GMP cleanroom environment + sterile water cooling |

IV. Smart Control System

- Dynamic Tension Control:

Substrate speed-extrusion sync (fluctuation <0.5%) + automatic eccentricity correction (±0.05 mm). - Cloud Recipe Platform:

Stores 100+ process parameters (e.g., temp curves for copper/wood) + real-time fault diagnosis (clogging/temperature alerts).

V. Technical Competitiveness

Extreme Coating Capabilities

| Parameter | Range |

|---|---|

| Thickness | 0.1 mm (TPU cables) → 5 mm (steel pipes) |

| Width | 10 mm (electronic wires) → 200 mm (profiles) |

Full-Spectrum Substrate Compatibility

- Rigid substrates: Steel/Al alloy (tensile strength >300 MPa)

- Flexible substrates: Glass fiber/wood (self-adaptive bending modulus)

Energy Optimization

- Electromagnetic pre-heating: ↓40% energy vs. resistive heating

- Waste heat recovery: Cuts cooling energy ↓30%

Target Users

Cable manufacturers (UL/CE certified), premium window producers, automotive part suppliers, medical device processors.

Upgrade Options

- Ultra-clean module (ISO Class 7 medical coating)

- Laser surface texturing (wood/leather grain transfer)

Certification Standards

- Adhesion: ASTM D903 peel strength >15 N/cm

- Thickness tolerance: ISO 3302-1 Class E

- High-speed stability: 80 m/min continuous operation 500 h zero fluctuation