Product Categories

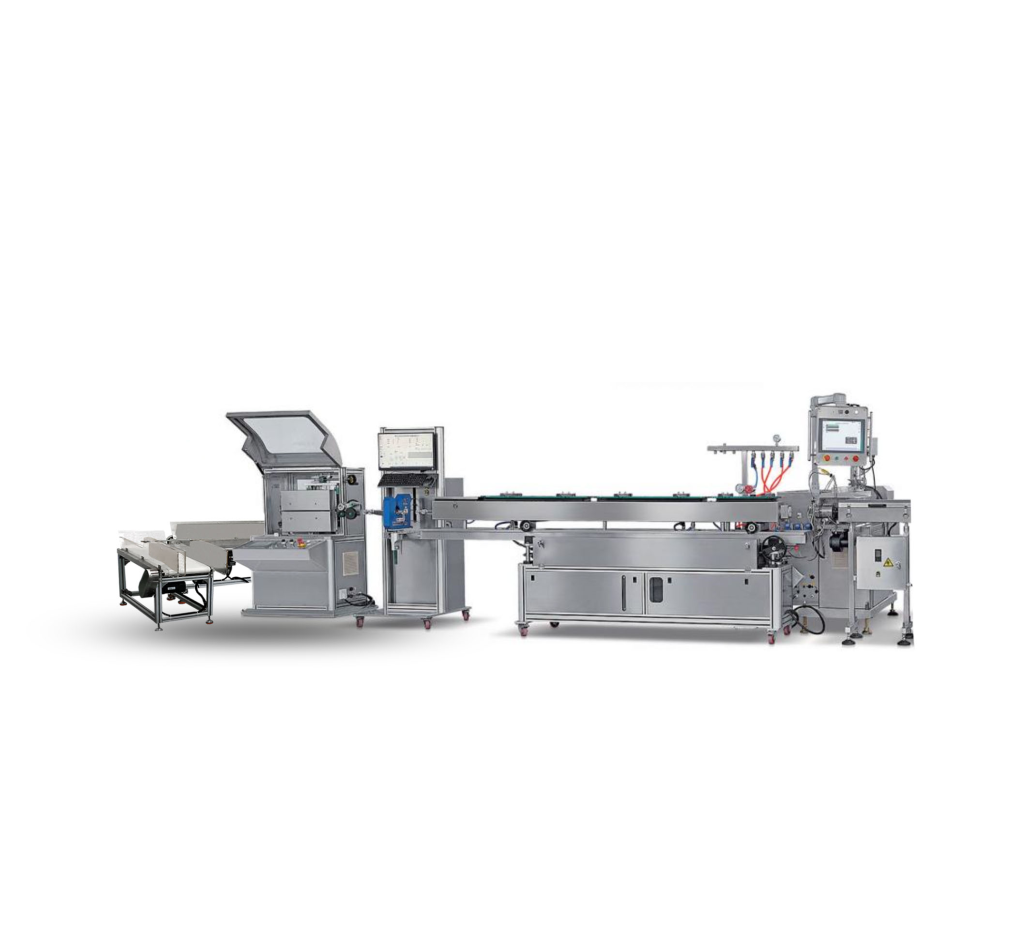

Cutting Machine

This cutting machine is a device used in the plastic extrusion production line to cut long plastic products (such as pipes, profiles, sheets, etc.) into specified lengths. Through precise cutting tools and a control system, the cutting machine ensures high cutting accuracy and smooth cut surfaces. According to different application requirements, the cutting machine can adopt hot cutting, cold cutting, or flying knife cutting methods.

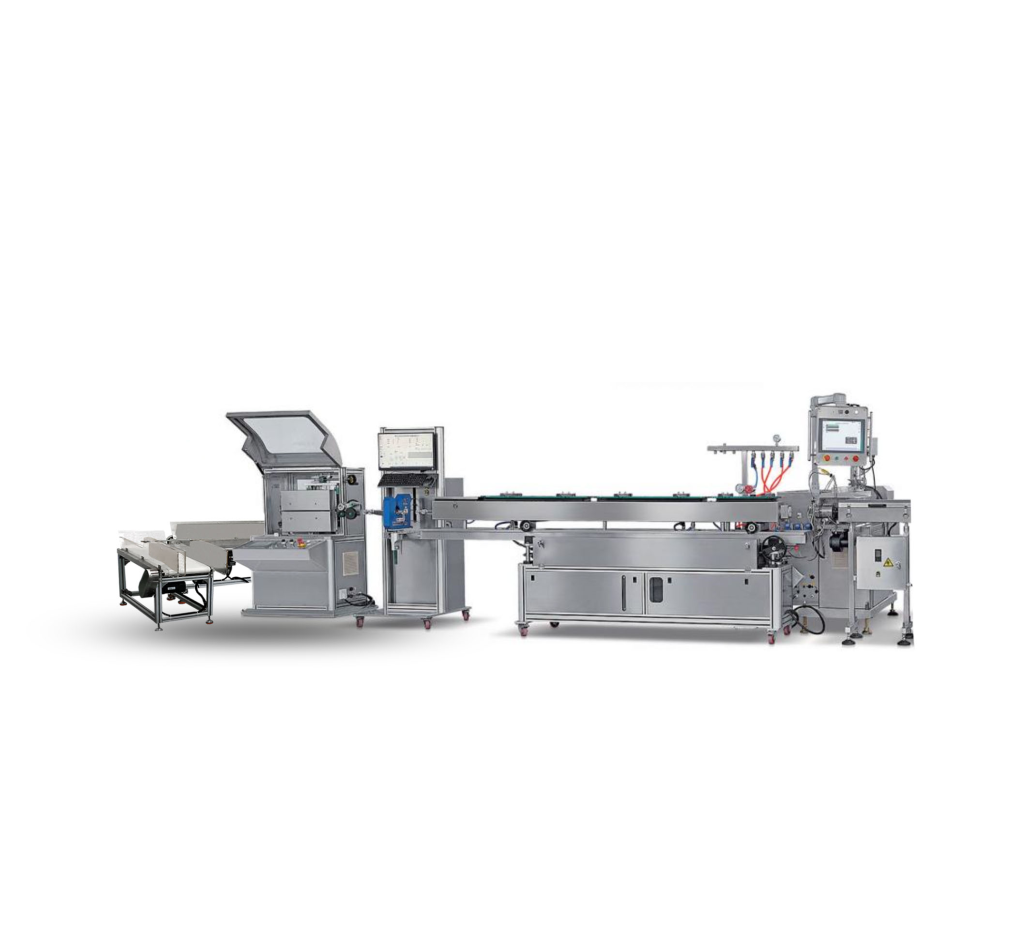

Mixer

This mixer is a device used to uniformly mix different types of plastic raw materials or other materials. In the plastic extrusion production line, the mixer is mainly used to mix recycled materials, additives, color masterbatches, etc., with the base plastic to ensure the uniformity of the materials and improve the quality of the final product. Common types of mixers include horizontal mixers, vertical mixers, and high – efficiency high – speed mixers.

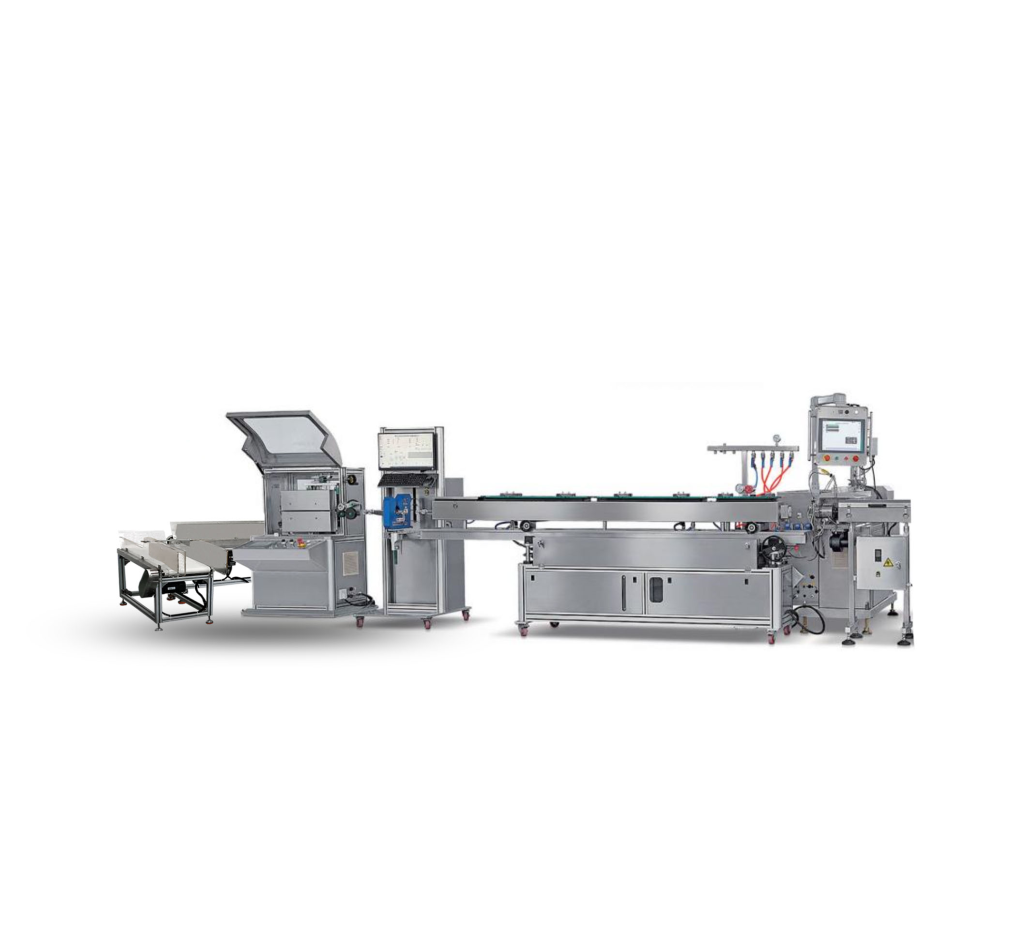

Dryer

This dryer is a device used to remove moisture from plastic raw materials in the plastic extrusion production line, which is especially crucial for plastics with strong hygroscopicity, such as PA, PET and other materials. The dryer quickly and effectively evaporates the moisture in plastic particles through methods such as heating, air circulation, or a vacuum environment, avoiding the negative impact of moisture on the melting, molding, and mechanical properties during the plastic processing. Common types of dryers include hot air dryers, vacuum dryers, and freeze dryers.

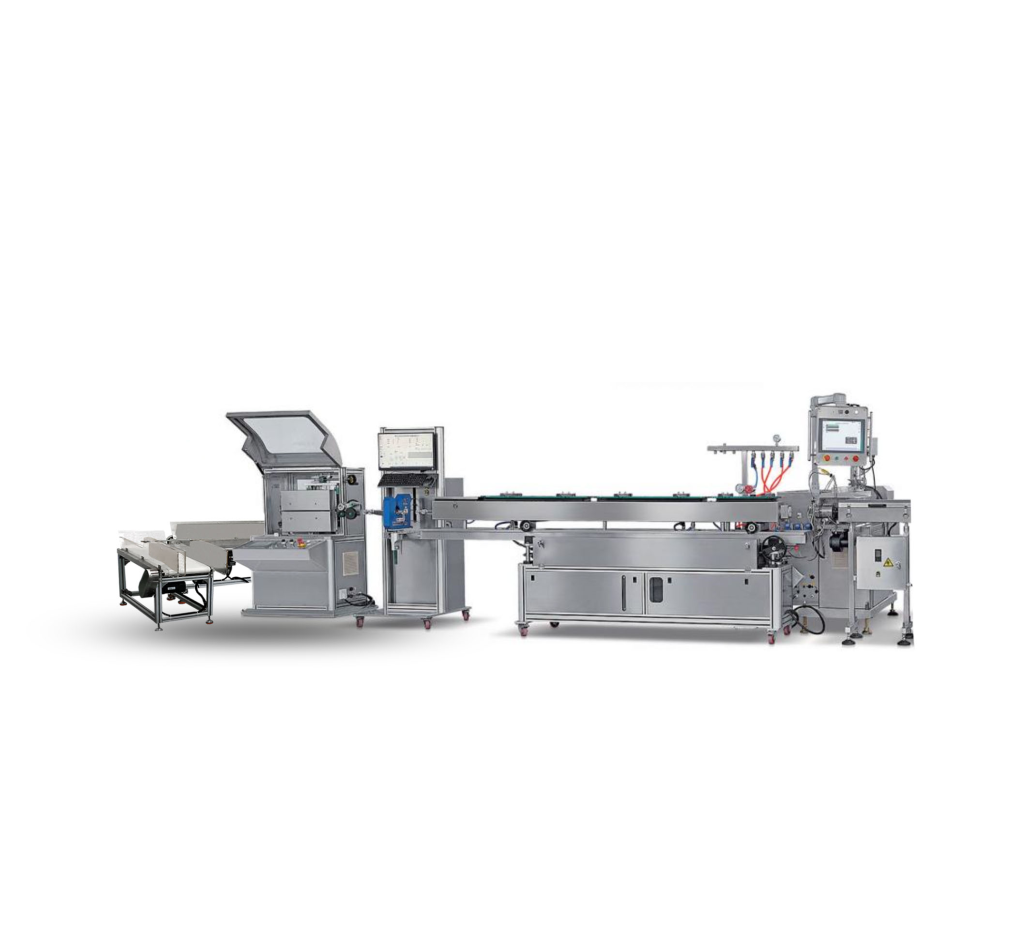

Chiller

This chiller is a key device used to control the temperature of equipment and products in the plastic extrusion production line, and it is especially suitable for production processes that require high – precision temperature control. The chiller provides low – temperature cooling water through a refrigeration cycle system to maintain the appropriate temperature of equipment such as extruders, molds, and cooling water tanks. It can work stably under different environmental conditions, effectively prevent equipment overheating, improve production efficiency, and extend the service life of equipment.