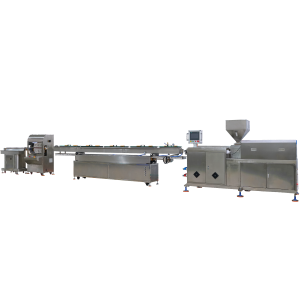

I. Foam Extrusion System: Multi-Material Compatibility & High-Precision Foam Control

Specialized Screw Design

- Parameter Adaptability: Screw diameter 50–120 mm, L/D ratio 25:1–30:1 (extendable to 34:1).

- Non-polar materials (PS/PE): Deep-feed section prevents bridging.

- Heat-sensitive materials (PVC/EVA): Gentle compression zone (ratio 2.8:1) reduces decomposition risk.

Foaming Agent Injection Optimization

- Physical Foaming Agents (N₂/CO₂):

- High-pressure nitrogen injection system (28.5 MPa) + barrier mixing section → foam uniformity deviation ≤5%.

- Chemical Foaming Agents (CBA):

- Independently temperature-controlled injection channel (±1°C) → prevents density variation.

Dual-Stage Pressure-Temperature Coupling

| Material | Barrel Temp. Zones (°C) | Foaming Agent | Pressure Control |

|---|---|---|---|

| PS | 160/180/190/185 | Physical | Backpressure stabilized at 20 MPa |

| PVC | 140/155/165/160 | Chemical | Pressure relief valve → anti-decomposition |

- Melt Gear Pump: Outlet pressure fluctuation ≤±0.5 MPa → eliminates cell collapse in ABS.

- Dynamic Cooling: Air/water-switchable cooling → quenching rate 15°C/s (PP) or slow cooling 5°C/min (EVA).

II. Precision Forming System: Multi-Mold Adaptability & Cell Structure Control

Modular Mold System

- Sheet Mold: Coat-hanger flow channel + lip thermal oil control (±0.5°C) → thickness tolerance ≤±0.1 mm for 1.5m-wide PS sheets.

- Pipe Mold: Spiral mandrel + gas-assisted calibration (0.2–0.5 MPa) → eliminates PVC pipe eccentricity.

- Profile Mold: Multi-stage cooling mold + air-water hybrid cooling → prevents PE surface sink marks.

Foam Stability Enhancement

- Nucleating Agent System: Nano-CaCO₃ pre-mixing → cell density ↑10⁶ cells/cm³ (vs. standard 10⁵).

- Online Capacitive Monitoring: Real-time foam density feedback + haul-off speed compensation (response time 0.1 s).

III. Smart Control System: Multi-Parameter Synergy & Defect Prediction

PLC-HMI Integrated Control

- Process Database: 50+ predefined recipes (e.g., EVA expansion ratio 20–40) → one-click switching.

Predictive Maintenance Module

- Vibration spectrum analysis → screw wear alert (>10% deviation).

- Current ripple monitoring → auto-speed reduction before motor overload.

IV. Production Line Integration: High-Speed Stability & Flexible Production

Haul-off & Cutting Integration

- Caterpillar Haul-off: Silicone-coated rollers (linear pressure 20 N/cm²) + servo sync → speed 50 m/min, deviation <0.05%.

- Planetary Cutting: Carbide blade (Φ450 mm) + hydraulic buffer → cutting vibration <5 μm (precision profiles).

Custom Winding System

- Auto Winder: Magnetic tension control (gradient 2–15 N) → coil end-face deviation <0.5 mm.

- Manual Mode: Pneumatic lift rack (3-ton capacity) → large-format sheet handling.

V. Typical Applications & Process Optimization

| Material | Product Type | Key Technical Measures | Peak Output |

|---|---|---|---|

| PS | Thermal insulation boards | High-pressure N₂ + coat-hanger die | 200 kg/h |

| EVA | Foam shoe soles | CBA + suspended air cooling | 150 kg/h |

| PVC | Foam pipes | Spiral mandrel + slow cooling | 120 kg/h |

| PP | Automotive interior trim | Nano-nucleating agent + air-water cooling | 180 kg/h |

Conclusion: Technical Barriers & Industry Value

The HPJX-FE-01 resolves two industry challenges—density gradient control (≤±3%) and cell uniformity (diameter deviation ±5 μm)—via multi-stage foam control (physical/chemical switching) and smart closed-loop systems (pressure-temperature-speed linkage). Its modular molds enable wide-speed production (10–50 m/min), while automatic winding supports applications from packaging (EPE foam) to construction insulation (XPS). Future digital twin integration may enable visual control of cell structures (e.g., >95% open-cell ratio for acoustic materials).