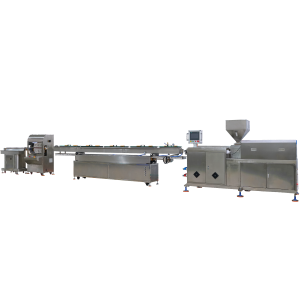

I. Extrusion System: Efficient Plasticization & Precision Conveying

Screw Design & Material Adaptability

- Screw Parameters: Diameter 65–120 mm, L/D ratio 28:1–33:1. High L/D ratio (e.g., 33:1) extends material residence time, enhancing plasticization uniformity—critical for temperature-sensitive materials (e.g., PVC, ABS).

- Multi-Material Compatibility: Dedicated screw structures for diverse materials:

- PP/PE: Deep-feed section + high-shear mixing segment → max. output 500 kg/h.

- PMMA/PC: Low-shear compression design prevents molecular chain degradation.

- Drive System: 30–110 kW AC variable-frequency motor + hardened gear reducer → speed 0–100 r/min stepless control, ensuring stable torque output.

Temperature Control & Melt Quality

- Zoned Heating: Barrel divided into 6–8 independent zones (±1°C precision); water-cooled feed section prevents bridging; air-cooled homogenization section avoids overheating.

- Melt Pump Assist: Optional gear pump enables quantitative/pressure-stable delivery → eliminates pressure fluctuations, sheet thickness tolerance ≤±0.05 mm.

II. Forming & Cooling System: Precision Thickness Control

Coat-Hanger Die Structure

- Adjustable lip width (up to 2500 mm), CFD-optimized flow channels ensure linear melt velocity → reduces edge thickening.

- Zoned die heating (±0.5°C) + hydraulic micro-bolts compensate for thermal deformation in real time.

Calendering & Cooling

- Calender Configuration: Vertical/inclined triple-roll design, mirror-polished surface (Ra≤0.2μm), supports glossy/matte/embossed textures.

- Dual-Mode Cooling:

Method Scenario Advantage Water-Cooled Rolls Thick sheets (>3 mm) Rapid cooling → prevents crystallization (e.g., PP) Air-Cooled + Mist Thin sheets (<1 mm)/optical-grade Eliminates water marks → enhances light transmittance

III. Haul-Off & Cutting System: High-Precision Processing

Haul-Off Mechanism

- Caterpillar Type: For thick sheets (e.g., 15 mm ABS); rubber-clad gripping surface prevents scratches; speed sync precision 0.1%.

- Roller Type: For thin films (e.g., 0.3 mm PET) → minimizes surface indentation.

Cutting & Winding Solutions

- Planetary Cutting: Circular saw groups synchronize with sheet movement → burr-free cut (±0.5 mm tolerance), supports fixed-length cutting.

- Chip-Free Cutting: Ultrasonic blade technology for recycled sheets → eliminates debris contamination.

- Winding System: Automatic winder with constant tension control (±2%), max. roll diameter 2500 mm; manual winding with pneumatic lift optional.

IV. Control System & Smart Technology

Core Control Unit

- PLC+HMI Integration: Real-time monitoring of pressure/temperature/speed; stores 100+ process recipes; one-click material switching.

- Intelligent Feedback:

- Beta-ray thickness gauge scans online → adjusts die bolts (response <0.5 s);

- Melt pump pressure closed-loop → flow fluctuation ≤±1%.

Energy Saving & Maintenance

- Electromagnetic heating replaces resistive heating → energy consumption ↓30%.

- Hydraulic screen changer (dual-position, 80–120 mesh) → extends continuous runtime.

V. Applications & Material Optimization

| Material | Typical Applications | Production Line Optimization |

|---|---|---|

| ABS/HIPS | Automotive interiors, fridge liners | Multi-layer co-extrusion (5-layer) → impact resistance ↑ |

| PP/PE | Food packaging, corrosion-resistant boards | High screw speed (100 r/min) + rapid cooling |

| PET/PMMA | Light guides, display panels | Low-shear plasticization + dust-free air cooling |

Conclusion: Technological Competitiveness & Customization

The HPJX-BSE-01 balances versatility and specialization through modular design (e.g., quick-change screws/dies) and intelligent control (e.g., thickness closed-loop feedback). Its core metrics—±0.05 mm thickness tolerance, 500 kg/h output—rival global benchmarks. Future upgrades may integrate IoT predictive maintenance to advance toward zero-defect manufacturing.