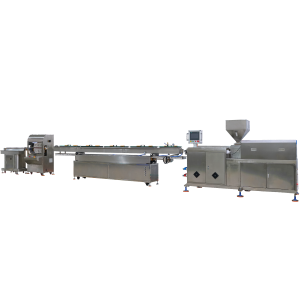

I. Equipment Overview & Core Functions

General pipe extruder production lines are core plastic processing systems for manufacturing PVC, PE, PP, PPR, ABS, and other material pipes. They serve civil and industrial applications including:

Building drainage/supply pipes

Gas pipelines

Cable conduits

Key Capabilities:

High-precision plastification control

Multi-die compatibility (solid, corrugated, composite pipes)

Continuous production for Ø50-200mm pipes

II. Core Components & Technologies

1. Main System

| Component | Specification |

|---|---|

| Screw Design | Single/twin screw (Ø50-75mm); Conical for PVC, parallel for PE/PP |

| Temperature Control | ±1°C accuracy; Zoned heating (4-6 sections) + air cooling |

| Drive System | Servo/VFD motor; ≤1% speed fluctuation; Up to 30m/min line speed |

2. Die & Flow Optimization

Multi-cavity dies: “Four-out” high-yield mode for Ø16-200mm pipes

Co-extrusion heads: Multi-layer/color capability (e.g., PPR + fiberglass reinforcement)

3. Cooling & Sizing

Vacuum spray tanks (SUS304; -0.08~-0.1MPa vacuum)

3D adjustment for complex profiles (±0.1mm roundness tolerance)

4. Haul-off & Cutting

Caterpillar haul-offs (8kN force; ≤0.1% sync error) for rigid pipes

Precision cutting: Circular saw (±0.5mm) for small pipes; Orbital cutter (±1mm) for large pipes

III. Material & Process Features

Material Properties

| Material | Processing Requirements |

|---|---|

| Rigid PVC | Conical twin-screw + degassing system |

| PE/PPR | Single-screw + melt gear pump (<5% pressure fluctuation) |

| Functional | Optimized screw mixing (e.g., antibacterial PE) |

Production Process

Pre-processing: High-speed mixing (500-1000 rpm; ≤0.02% moisture)

Extrusion: Screw speed 20-90 rpm; Head pressure 15-40 MPa; Melt temp ±2°C

QC: Laser micrometer (0.01mm precision) + IR thermometer + PLC feedback

IV. Applications & Selection Guide

| Sector | Product Examples |

|---|---|

| Construction | PVC drainage (Ø50-160mm); PPR pipes (Ø50-110mm) |

| Municipal | HDPE corrugated (Ø16-63mm); PE gas (Ø50-200mm) |

| Industrial | PPS heat-resistant (Ø50-100mm); PU hydraulic (Ø6-50mm) |

V. Industry Trends

Smart Manufacturing: IoT remote monitoring + torque anomaly alerts

Energy Efficiency: Electromagnetic heating (30-40% energy savings)

Advanced Co-extrusion: 5-layer structures (barrier/adhesive/core layers)

Sustainability: Biodegradable materials (e.g., PLA) compatibility

Conclusion

General pipe extruder production lines achieve full-range production (capillary to large engineering pipes) through modular design (e.g., quick-die-change) and intelligent control. Future evolution focuses on energy efficiency and material versatility.