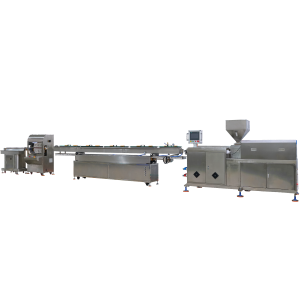

I. Equipment Overview

The HPJX-PFE-01 is a high-performance, multi-purpose plastic extrusion line designed for producing complex cross-section profiles. Its core strengths include broad material adaptability, flexible dimensional adjustment, and stable extrusion efficiency, making it ideal for profile manufacturing in construction, home furnishing, automotive, and electronics industries.

II. Core Parameter Analysis

Extruder Model & Material Compatibility

- Model: HPJX-PFE-01 (modular design for easy maintenance and functional expansion).

- Applicable Materials: PVC (rigid/flexible), PP, PE, ABS, PS, TPE (thermoplastic elastomer), ASA (weather-resistant engineering plastic), PMMA (acrylic), etc. Covers diverse physical properties (strength, toughness, weather resistance).

Production Specifications

- Profile Dimensions: Height/width 5–200 mm (supports narrow decorative strips, wide window frames, hollow pipes).

- Mold Adaptability: Universal mold system enables rapid changeovers (downtime minimized).

Extrusion Performance & Configuration

- Max. Output: Tiered options – 150/250/350 kg/h (corresponding to screw diameters: 60/75/90 mm; motor power: 22/37/45 kW).

- Screw Design: L/D ratio 25:1–30:1 optimizes plasticization uniformity; high compression ratio suits filled/recycled materials.

Temperature Control & Drive System

- Zoned Heating: 4–6 independent PID zones (±1°C precision), adaptable to material melting traits (e.g., low temp. for PVC decomposition prevention, high temp. for PP).

- Drive Motor: Variable-frequency motor + high-torque gearbox → stepless speed control.

III. Key Production Line Components

Main Extrusion Unit

- Extrusion Module: Bimetallic alloy barrel bushings (wear/corrosion resistant); forced air/water cooling ensures long-term stability.

- Feeding System: Optional gravimetric or forced feeder for powder/pellet materials.

Mold & Calibration

- Die Flow Design: Multi-stage分流compression balances melt flow → reduces internal stress.

- Vacuum Calibration: Sectional water-cooled vacuum tank (±0.1 mm dimensional tolerance).

Auxiliary Equipment

- Haul-off: Dual-track caterpillar haul-off (speed sync precision 0.5%) → prevents deformation.

- Cutter: Servo-driven flying saw or planetary cutter (burr-free cuts).

- Stacking System: Automatic turnover or pallet collection; robotic palletizing optional.

IV. Technological Highlights

Energy Efficiency

- IE4 high-efficiency motor + electromagnetic heating → energy consumption ↓15–20%.

Intelligent Control

- PLC+HMI Integration: Stores 100+ recipes; real-time fault diagnosis + remote monitoring.

High Compatibility

- Supports masterbatches, flame retardants, and functional additives; enables online co-extrusion (e.g., dual-color profiles).

V. Typical Applications

| Industry | Products |

|---|---|

| Construction | PVC window profiles, ASA sunshades |

| Automotive | ABS seals, TPE bumper guards |

| Electronics | PS wire ducts, PMMA light guides |

VI. Configuration Recommendations

- Small-Batch Multi-Variety: 60 mm screw + 150 kg/h → flexible pilot production.

- Mass Production: 90 mm screw + 350 kg/h + automated line → maximizes efficiency.

Conclusion

The HPJX-PFE-01 excels through modular versatility, material adaptability, and stable output, positioning it as the optimal choice for SMEs tackling diverse market demands. Its tiered configurations empower users to balance flexibility and productivity seamlessly.