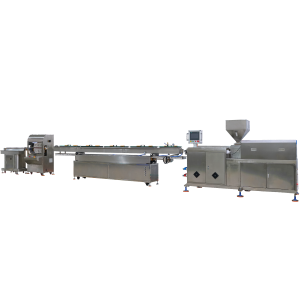

I. Multi-Material Extrusion System: High-Efficiency Plasticization & Devolatilization

Modular Screw Design

- Vented Structure: Screw diameter 45–150 mm, L/D ratio 20:1–30:1 (extendable to 32:1).

- Non-polar polymers (PE/PP): Deep-feed section + barrier mixing → max. output 500 kg/h .

- Heat-sensitive materials (PVC/EVA): Gentle compression (ratio 2.5:1) + zoned air/water cooling (±1°C) .

- Two-Stage Vacuum Devolatilization: Vacuum level -0.095 MPa → removes moisture/volatiles from TPU/PA (residual rate <0.01%) .

Temperature-Shear Synergy Control

| Material | Plast. Temp. (°C) | Optimization Measures |

|---|---|---|

| TPE/TPU | 160–190 | Low-shear barrier flights + electromagnetic heating (↓30% energy) |

| PET | 270–290 | Melt gear pump stabilizes pressure (±0.5 MPa) |

II. Multi-Mode Pelletizing: Precision & Cooling Optimization

Tri-Mode Pelletizing Comparison

| Method | Materials | Pellet Shape | Cooling | Max. Speed |

|---|---|---|---|---|

| Water Ring | PP/PE/PET | Spherical (Φ2–3 mm) | Mist quenching (10–15°C) | 80 m/min |

| Air Cooling | TPE/TPU | Cylindrical (L/D=1.5) | Suspended air cooling (2 m/s) | 50 m/min |

| Cold Cutting | PVC/ABS | Cubic | Staged water tank | 30 m/min |

- Swirl Water Ring Pelletizing: Centrifugal dewatering ↑40% efficiency (residual moisture <0.1%); carbide blades (HRC≥60) → vibration <5 μm .

Pellet Uniformity Control

- Laser Gauging: 1 kHz sampling + cutter speed compensation (0.2 s response) → tolerance ±0.05 mm.

- Nano-Nucleating Agent: CaCO₃ pre-mixing (0.1–0.5%) → recycled PE density ↑10⁶ cells/cm³ .

III. Smart Control: Multi-Parameter Coupling & Energy Management

PLC-HMI Integration

- Process Database: 50+ predefined recipes (e.g., PA crystallization window, TPU melt strength curve) .

- Triple Closed-Loop: Melt pressure sensor + pellet vision + motor current → dynamically adjusts screw speed, pelletizing rate & coolant flow .

Energy Optimization

- Electromagnetic heating → thermal efficiency ↑92% (vs. 70% resistive) .

- Load-adaptive algorithm: Motor power 7.5–90 kW stepless; no-load consumption <10% of full load .

IV. Applications & Throughput Breakthroughs

| Material | Product Type | Key Innovation | Peak Output |

|---|---|---|---|

| Recycled PET | Bottle flakes | Two-stage venting + melt pump | 400 kg/h |

| TPE | Elastomer pellets | Suspended air cooling + low-shear plast. | 150 kg/h |

| PA6 | Engineering pellets | Vacuum devolatilization + water ring pellet. | 300 kg/h |

| PVC | Cable compound | Cold cutting + nano-agent anti-powdering | 200 kg/h |

V. Green Manufacturing & Maintenance

- Heat Recovery: Extrusion waste heat → hopper drying (↓18% energy) .

- Closed Water Loop: Reuse rate >95% → national green factory compliance .

- Predictive Maintenance: Vibration analysis → screw wear alert (>10% lifespan deviation) .

Conclusion: Technical Barriers & Industry Value

The HPJX-GE-01 resolves two industry-wide challenges—devolatilization efficiency (residuals <0.01%) and elastomer pellet adhesion—via modular screws (quick-change venting) and tri-mode pelletizing (water ring/air cooling/cold cutting). Its core metrics—500 kg/h output, 80 m/min cutting speed, and ±0.05 mm pellet tolerance—surpass leading international models. Future digital twin integration may enable real-time crystal optimization (e.g., >85% α-crystals in PA66), advancing recycled plastic pelletizing toward molecular-level precision .