I. Core Parameters & Functional Positioning

Core Parameters

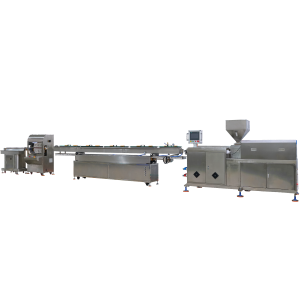

- Model: HPJX-PE-02 (modular design, adaptable to multi-scenario demands)

- Applicable Materials: PVC, HDPE, PPR, PP, PA, PVDF, PEEK, etc. (covers municipal, chemical, and construction engineering plastics)

- Pipe Diameter Range: 50–200 mm (supports thick-walled pipes e.g., gas pipes & thin-walled pipes e.g., cable conduits)

- Max. Output: 400/800/1000 kg/h (capacity tiered via screw replacement)

Functional Positioning

- Designed for industrial-grade pipes requiring high strength, corrosion resistance, and pressure endurance (e.g., chemical pipelines, gas pipes)

- Supports multi-layer co-extrusion for oxygen-barrier/reinforced-layer composite pipes.

II. Core Components & Technological Innovations

Screw System

- Screw Configurations: 75/90/120 mm diameters; L/D ratio 28:1 (standard) or 30:1 (high-plasticization demand); 38CrMoAlA nitrided steel (wear resistance ↑50%)

- Drive System: 30/45/55 kW servo motor + hardened gear reducer (extrusion speed fluctuation ≤0.8%).

Temp Control & Plasticization

- Zoned Heating: 4–6 independent zones (±1°C precision), optimized per material (e.g., PVC: 160–190°C; PEEK: 350–400°C)

- Forced Feeding: Dual-stage feeder ensures uniform intake for high-viscosity materials (e.g., PVDF).

Mold & Calibration

- Quick Mold Change: Modular die design (changeover ≤30 min)

- Vacuum Calibration Tank: SUS304 stainless steel (-0.1 MPa vacuum) + multi-stage spray cooling (pipe roundness tolerance ±0.15 mm).

III. Production Process & Material Adaptation

Typical Process Flow

- Preprocessing: High-speed mixer (500–1000 rpm) ensures homogeneous dispersion of dry blends (humidity ≤0.03%)

- Extrusion: Screw speed 20–80 rpm; die pressure 20–45 MPa; melt temp deviation ±2°C

- Online QC: Integrated laser micrometer (0.02 mm precision) + IR thermal imager feeds real-time data to PLC.

Material-Specific Adaptation

- HDPE/PPR: Single-screw + melt gear pump (pressure fluctuation <5%), supports high-speed extrusion (20 m/min)

- PVDF/PEEK: Bimetallic barrel + specialized mixing section (temp resistance 400°C), meets semiconductor/chemical pipeline demands.

IV. Typical Applications

Municipal Engineering

- HDPE double-wall corrugated pipes (DN200–600 mm, ring stiffness SN8)

- PVC drainage pipes (DN50–200 mm, compliant with GB/T 5836).

Industrial Sector

- PVDF chemical corrosion-resistant pipes (wall thickness 2–10 mm, pH 1–14 resistance)

- PEEK ultra-high-pressure pipes (working pressure ≥32 MPa, for oil exploration).

V. Smart & Energy-Saving Design

Intelligent Control

- IoT remote monitoring enables fault预警 (e.g., torque overload alarm) & self-optimizing process parameters

- MES system integration for automated production data upload.

Energy Efficiency

- Electromagnetic induction heating replaces resistive heating (energy consumption ↓35%)

- Waste heat recovery system recycles cooling water heat for raw material pre-drying.

Conclusion

The HPJX-PE-02 achieves full-spectrum processing from conventional to specialty engineering plastics via modular screw systems, precision temp control, and smart management. Its 1000 kg/h max. output meets large-scale municipal project demands, while the 30:1 L/D screw ensures high-quality plasticization of challenging materials like PEEK. Future upgrades may include five-layer co-extrusion die technology to expand composite pipe capabilities.

Note: Technical terms (e.g., L/D ratio, SUS304, SN8) retain industry-standard abbreviations for global readability.